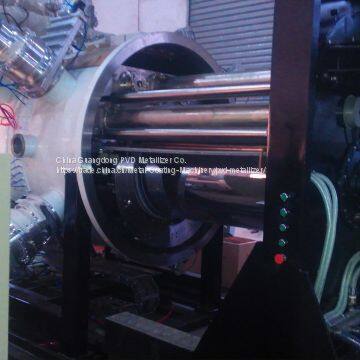

Model TS-2440CJXW magnetron sputtering line

Model TS-2440CJXW magnetron sputtering line for aluminum mirror coating (here-in after refered to as production line) has characteristics of small area taken, high stability in coating process and the operation of automation as well as visualization, etc., adaptable in the manufacture of stainless steel mirror or aluminum mirror glass.

The production line includes 3 process equipments: 1), glass cleaning by glass washer, 2), glass vacuum coating by PVD deposition system, 3), lacquering on coated glass to protect coated layer from damages by lacquer spraying machine. These equipments are integrated organically in technology to realize consecutive production with satisfactory results.

Alex Li

Mobile: 86 13929890858

Wechat: metallizer

Skype: vacuum-metallizer

Email: vacuumsale@hotmail.com

598828529@qq.com

Website: http://www.pvd-metallizer.com

Recently Posted

-

Ion-assisted deposition

May 31, 2017Ion-assisted deposition http://www.pvd-metallizer.com In ion-assisted deposition (IAD), the substrate is exposed to a se Read More

Read More -

Reactive sputtering

May 31, 2017Reactive sputtering http://www.pvd-metallizer.com In reactive sputtering, the sputtered particles undergo a chemical rea Read More

Read More -

Ion-beam sputtering

May 31, 2017Ion-beam sputtering http://www.pvd-metallizer.com Ion-beam sputtering (IBS) is a method in which the target is external Read More

Read More -

Types of sputter deposition

May 31, 2017Types of sputter deposition http://www.pvd-metallizer.com Sputtering sources often employ magnetrons that util Read More

Read More