Kaixuan Vacuum Technology

Main Products: Manufacturing line for amorphous silicon PV solar cells, Sputtering coating line for Low-E or ITO glass, Manufacturing line for CIGS solar cell, Smart sputtering-optical coater of auto loading , Cathodic Arc PVD coater for hard film deposition, Sputtering web coater, Continuous production line for VIP sealing, Vacuum Sealing Machine for VIP, Wire-feeding web coater, Anti-fingerprint vacuum coater, Thermal evaporation coater, E-beam optical coater

Home > Company Introduction

Company Overview

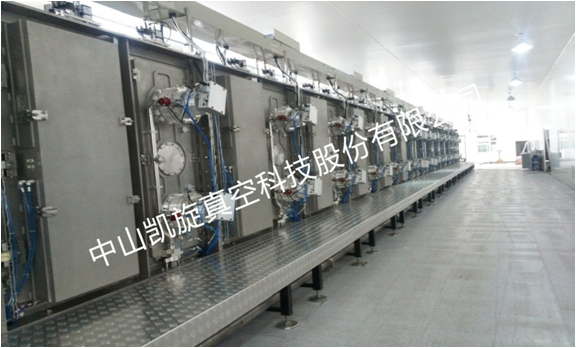

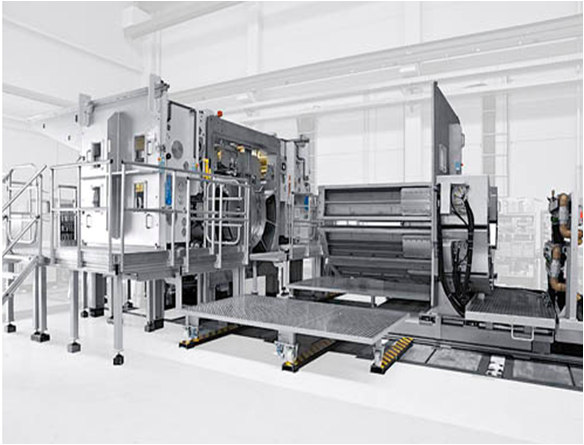

Kaixuan Vacuum Technology Co., Ltd. All the PVD metallizers look similar but those made by Kaixuan Vacuum Technology Co., Ltd. are surely different and unique. The main products as following: 1, Manufacturing line for amorphous silicon PV solar cell;2, Manufacturing line for CIGS solar cell;3, Continuous production line for VIP sealing;4, Vacuum Sealing Machine for VIP;5, Smart sputtering-optical coater of auto loading & unloading system;6, General sputtering coater;5, E-beam optical coater;6, Cathodic Arc PVD coater for hard film deposition;7, Sputtering coating line for Low-E or ITO glass;8, PVD Deposition of Black Hard Films of Ti/TiN/Ti(N,C)/TiC by PVD Coater of Cylindrical Arc Source;9, Web coaters for ITO or flexible solar cell and FPC coating;10, Sputtering web coater;11, Thermal evaporation coater;12, Anti-fingerprint vacuum coater. Kaixuan Vacuum Technology Co., Ltd. Alex LiMobile: 86 13929890858Wechat: metallizerSkype: vacuum-metallizerEmail: vacuumsale@hotmail.com

-

ManufacturerBusiness Type

-

1998Year Established

-

3,000-5,000 square metersFactory Size

-

US$1.5 Million - US$2.5 MillionAnnual Export Value

Company Detail

Transparency is the foundation of our partnership. Below is a comprehensive overview of our operational metrics, from business scale to global market reach, giving you a clear picture of our capabilities.

-

51 - 100 People Total Employees

-

11-20 People Sales Staff

-

10-20 People Quality Inspectors

-

ISO9001 Product Certifications

-

US$1.5 Million - US$2.5 Million Annual Export Value

-

North America, South America, Eastern Europe, Southeast Asia, Africa, Oceania, Mid East, Eastern Asia, Western Europe, Central America, Northern Europe, Southern Europe, South Asia, Domestic Market Main Markets

-

Shenzhen Port of Shipment

-

Metal Processing Machinery Parts Main Industry

-

Our ServicesWe produce many advanced vacuum metallizers or vacuum coating machines for various industrial purposes, extensively used in many industries. Our magnetron sputtering coating line for Low-E glass or plasma coating line for amorphous silicon PV solar cell should be competitive for its moderate price and reliable quality. As being the manufacturer in vacuum field, we can produce any vacuum coaters with various functions as per customer’s requirements. The main products as following: 1, Manufacturing line for amorphous silicon PV solar cells; 2,Continuous production line for VIP/STP vacuum insulated panel; 3, Sputtering coater; 4, E-beam optical coater; 5, Cathodic Arc PVD coater; 6, Magnetron sputtering coating line for Low-E or ITO glass; 7, Hubcap sputtering coater; 8, Wire-feeding web coater; 9, Sputtering web coater; 10, Thermal evaporation coater; 11, Vacuum pumps in series. Best regards. China Guangdong PVD Metallizer Co. Alex Li Mobile: +86 13929890858 Wechat: metallizer Skype: vacuum-metallizer Email: vacuumsale@hotmail.com 598828529@qq.com Website: http://www.pvd-metallizer.com

Our ServicesWe produce many advanced vacuum metallizers or vacuum coating machines for various industrial purposes, extensively used in many industries. Our magnetron sputtering coating line for Low-E glass or plasma coating line for amorphous silicon PV solar cell should be competitive for its moderate price and reliable quality. As being the manufacturer in vacuum field, we can produce any vacuum coaters with various functions as per customer’s requirements. The main products as following: 1, Manufacturing line for amorphous silicon PV solar cells; 2,Continuous production line for VIP/STP vacuum insulated panel; 3, Sputtering coater; 4, E-beam optical coater; 5, Cathodic Arc PVD coater; 6, Magnetron sputtering coating line for Low-E or ITO glass; 7, Hubcap sputtering coater; 8, Wire-feeding web coater; 9, Sputtering web coater; 10, Thermal evaporation coater; 11, Vacuum pumps in series. Best regards. China Guangdong PVD Metallizer Co. Alex Li Mobile: +86 13929890858 Wechat: metallizer Skype: vacuum-metallizer Email: vacuumsale@hotmail.com 598828529@qq.com Website: http://www.pvd-metallizer.com -

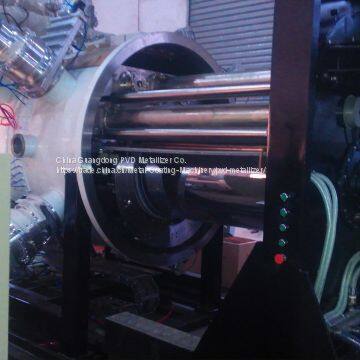

Company HistoryNewly invented Cathodic Arc PVD Coater for razor blade coating A specially designed model of Cathodic Arc PVD Coater came into being in recent years with special deposition purposes for the substrates, razor blades of well-known brands by the aids of special fixtures perfectly fit. Equipped with a turbo-molecular pump of Oerlikon LayBold, coupled with several mechanical pumps in vacuum evacuation, the newly invented machine enables itself to realize high efficiency and perfect precision in oriented coating on the substrates, received popularity from home and abroad. It is worth our while to promote this model of machine to the international market. Alex Li Mobile: +86 13929890858 Wechat: metallizer Skype: vacuum-metallizer Email: vacuumsale@hotmail.com 598828529@qq.com Website: http://www.pvd-metallizer.com

Company HistoryNewly invented Cathodic Arc PVD Coater for razor blade coating A specially designed model of Cathodic Arc PVD Coater came into being in recent years with special deposition purposes for the substrates, razor blades of well-known brands by the aids of special fixtures perfectly fit. Equipped with a turbo-molecular pump of Oerlikon LayBold, coupled with several mechanical pumps in vacuum evacuation, the newly invented machine enables itself to realize high efficiency and perfect precision in oriented coating on the substrates, received popularity from home and abroad. It is worth our while to promote this model of machine to the international market. Alex Li Mobile: +86 13929890858 Wechat: metallizer Skype: vacuum-metallizer Email: vacuumsale@hotmail.com 598828529@qq.com Website: http://www.pvd-metallizer.com -

Our TeamTypes of sputter deposition http://www.pvd-metallizer.com Sputtering sources often employ magnetrons that utilize strong electric and magnetic fields to confine charged plasma particles close to the surface of the sputter target. In a magnetic field, electrons follow helical paths around magnetic field lines, undergoing more ionizing collisions with gaseous neutrals near the target surface than would otherwise occur. (As the target material is depleted, a "racetrack" erosion profile may appear on the surface of the target.) The sputter gas is typically an inert gas such as argon. The extra argon ions created as a result of these collisions lead to a higher deposition rate. The plasma can also be sustained at a lower pressure this way. The sputtered atoms are neutrally charged and so are unaffected by the magnetic trap. Charge build-up on insulating targets can be avoided with the use of RF sputtering where the sign of the anode-cathode bias is varied at a high rate. RF sputtering works well to produce highly insulating oxide films but with the added expense of RF power supplies and impedance matching networks. Stray magnetic fields leaking from ferromagnetic targets also disturb the sputtering process. Specially designed sputter guns with unusually strong permanent magnets must often be used in compensation. China Guangdong PVD Metallizer Co. Alex Li Mobile: +86 13929890858 Wechat: metallizer Skype: vacuum-metallizer Email: vacuumsale@hotmail.com 598828529@qq.com Website: http://www.pvd-metallizer.com

Our TeamTypes of sputter deposition http://www.pvd-metallizer.com Sputtering sources often employ magnetrons that utilize strong electric and magnetic fields to confine charged plasma particles close to the surface of the sputter target. In a magnetic field, electrons follow helical paths around magnetic field lines, undergoing more ionizing collisions with gaseous neutrals near the target surface than would otherwise occur. (As the target material is depleted, a "racetrack" erosion profile may appear on the surface of the target.) The sputter gas is typically an inert gas such as argon. The extra argon ions created as a result of these collisions lead to a higher deposition rate. The plasma can also be sustained at a lower pressure this way. The sputtered atoms are neutrally charged and so are unaffected by the magnetic trap. Charge build-up on insulating targets can be avoided with the use of RF sputtering where the sign of the anode-cathode bias is varied at a high rate. RF sputtering works well to produce highly insulating oxide films but with the added expense of RF power supplies and impedance matching networks. Stray magnetic fields leaking from ferromagnetic targets also disturb the sputtering process. Specially designed sputter guns with unusually strong permanent magnets must often be used in compensation. China Guangdong PVD Metallizer Co. Alex Li Mobile: +86 13929890858 Wechat: metallizer Skype: vacuum-metallizer Email: vacuumsale@hotmail.com 598828529@qq.com Website: http://www.pvd-metallizer.com